TURNKEY MANUFACTURING

RHINE mechatronics renders engineering design solutions for production and machines. Our engineering philosophy follows the principle that a process solution that can not be simulated also can not be commissioned and that digital design verification precedes effective optimization.

Our multidisciplinary engineering team offers a project portfolio that includes a diverse set of technologies and disciplines.

Condition Based Monitoring > PLCs, robots and sensors should be monitored 24/7 via your IOT network for automated reporting and predictive maintenance.

Electrical Design > Electrical solutions bring mechanical assemblies to life. Schematics record the connection of electrical components, systems and machines.

Fieldbus Systems > Robots, controllers, machines and sensors interconnect to transmit binary data for effective production control using IOT technologies.

Machine Design > We are experienced in CE, TÜV and SANS certification for in-house designed machines.

Mobile Transport Robots > Automate material handling between your production cells and warehouse with our mobile transport robotics solutions.

Material Handling Systems > Efficient overhead and floor conveyors improve production rates in automotive plants and transfer and buffer materials or assemblies.

Programmable Logic Control > As part of our core business we develop control software, its simulation, support and commisioning.

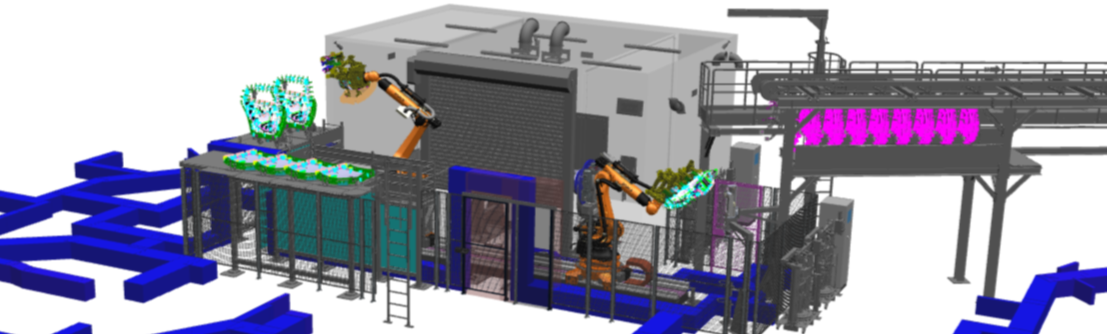

Robotic Production Cells > Welding, handling, hemming, palletizing, cutting, milling and screwing.

SCADA > Management and visualisation of production processes using real-time data.

Sensor Networks > Sensing encompasses a range of applications such as machine safety, presence detection, positioning, measurement and identification.

Tooling > 3D design of parts, jigs and fixtures along with applicable material strength and strain analysis.

Virtual Commisioing > Our team ensures that your process specifications are met long prior to commissioning.